Production at MECHATRONYX S.r.l. involves small-medium production lots and pre-series, a series of integrated phases and processes that combine mechanics, electronics, information technology and automatic control to create complex and innovative products.

Mechatronyx guarantees 100% traceability of production phases thanks to the implementation of an innovative MES system.

Testing and repairing mechatronic systems are critical steps in ensuring the reliability, functionality, and longevity of products. The process involves a series of structured activities designed to identify and correct problems that may arise during production or operation.

Below are some of our machines on the production line.

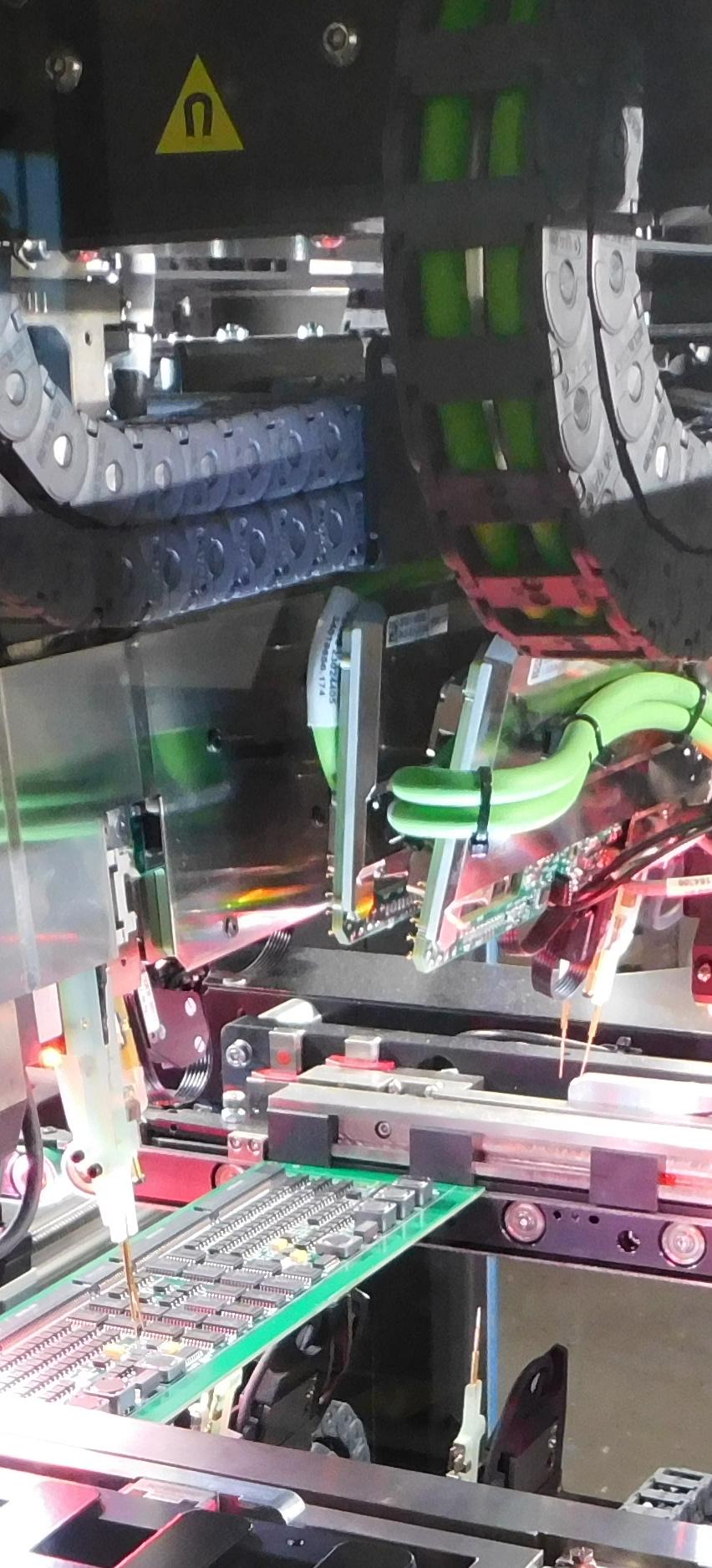

FLYING PROBE TESTING

N. 3 SPEA: 4080U/4080L/4060S2

- Large table size 1200 x 660 mm

- Rapid testing with 8 probes and new high-speed axes

- Small pitch, up to 100um

- Soft-touch probing

- High sensitivity for minimum leakage current test value of 2.5 Na

- Electrical scanning for testing of inaccessible BGA points

- OBP for automatic activation of microprocessor firmware or memory

- IN-CIRCUIT TEST

- SHORT CIRCUIT TEST

- NODAL IMP. TEST

- POWER ON-OFF TEST

- FUNCTIONAL TEST

- MICRO FLASHING

- REVERSE ENGINEERING

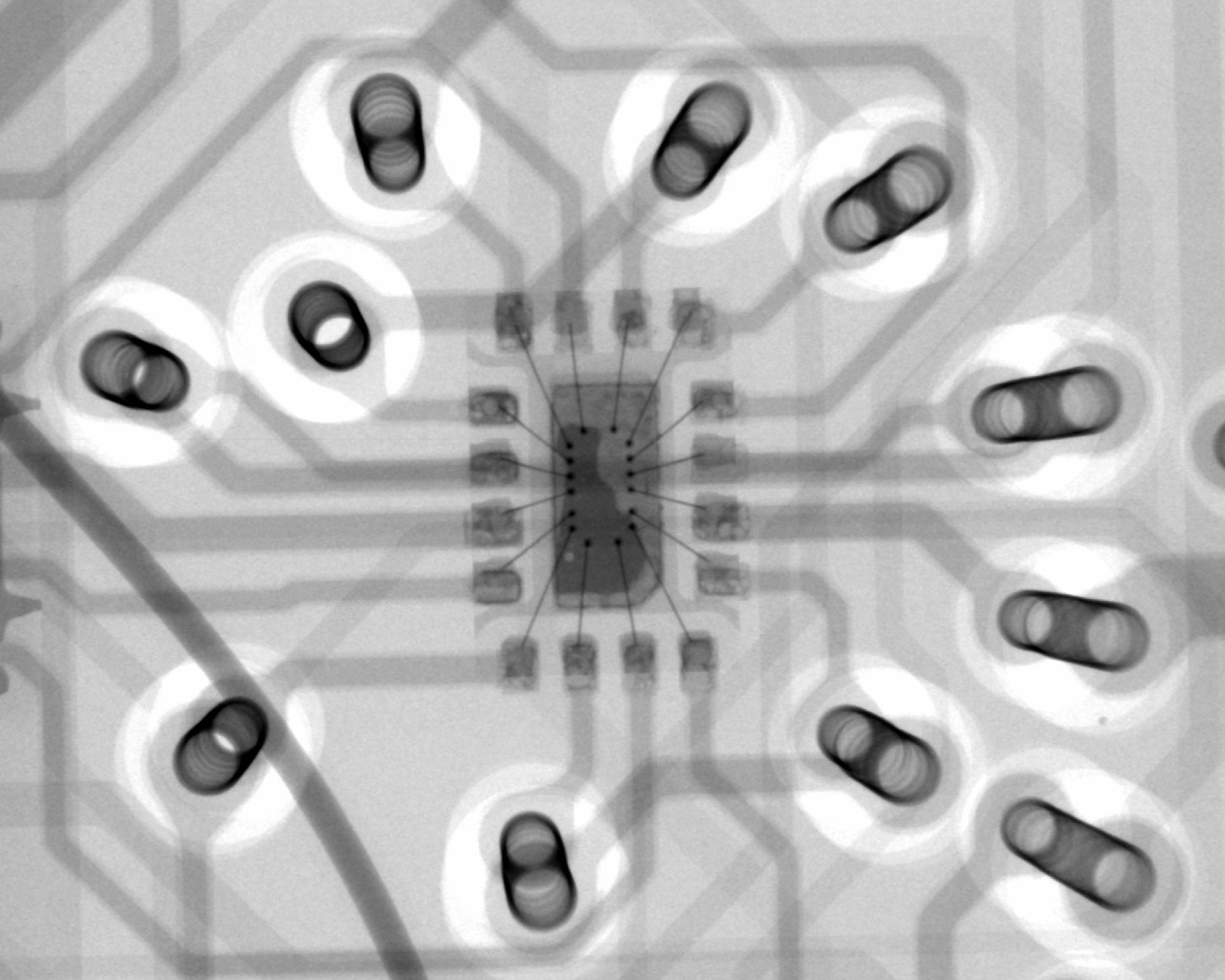

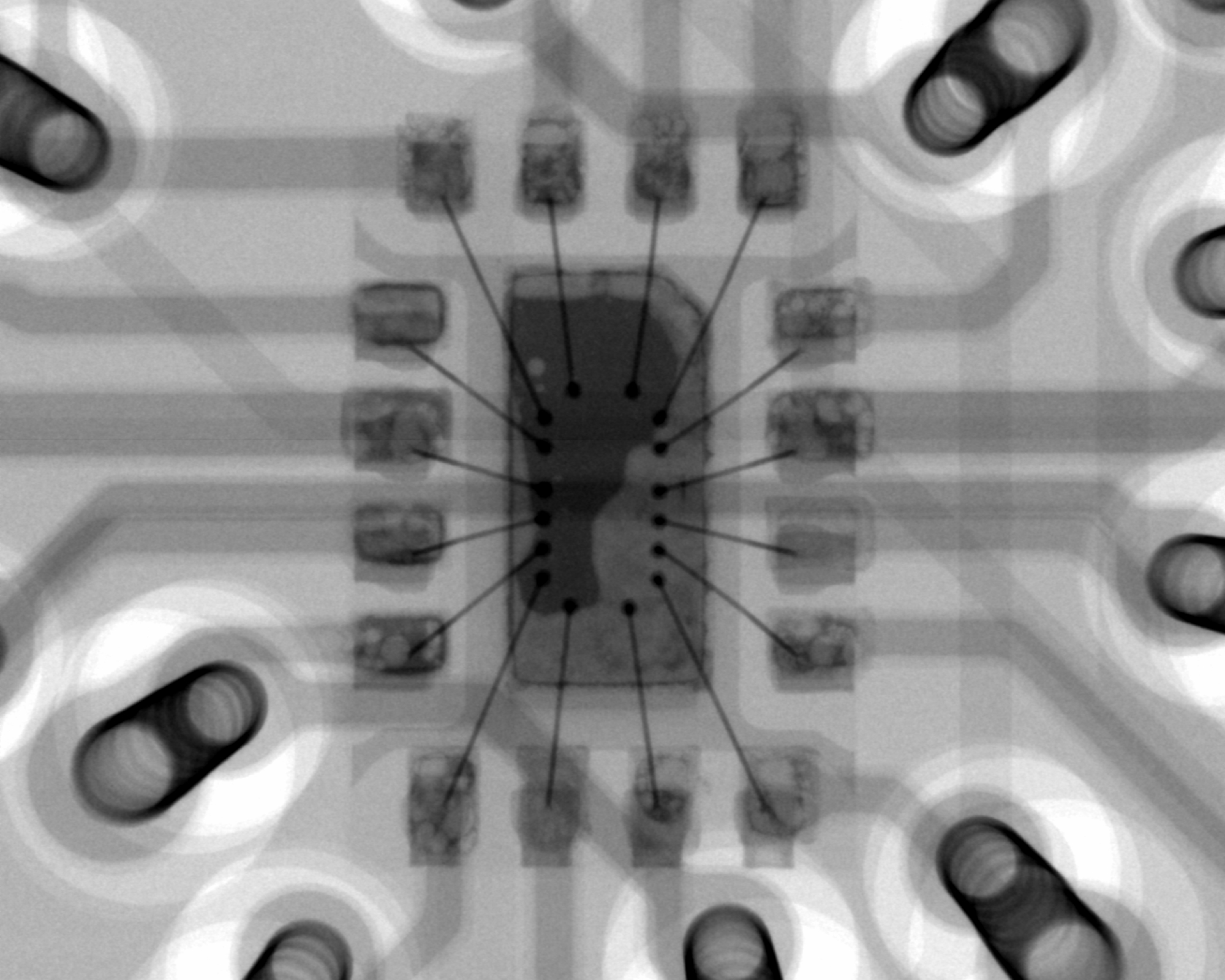

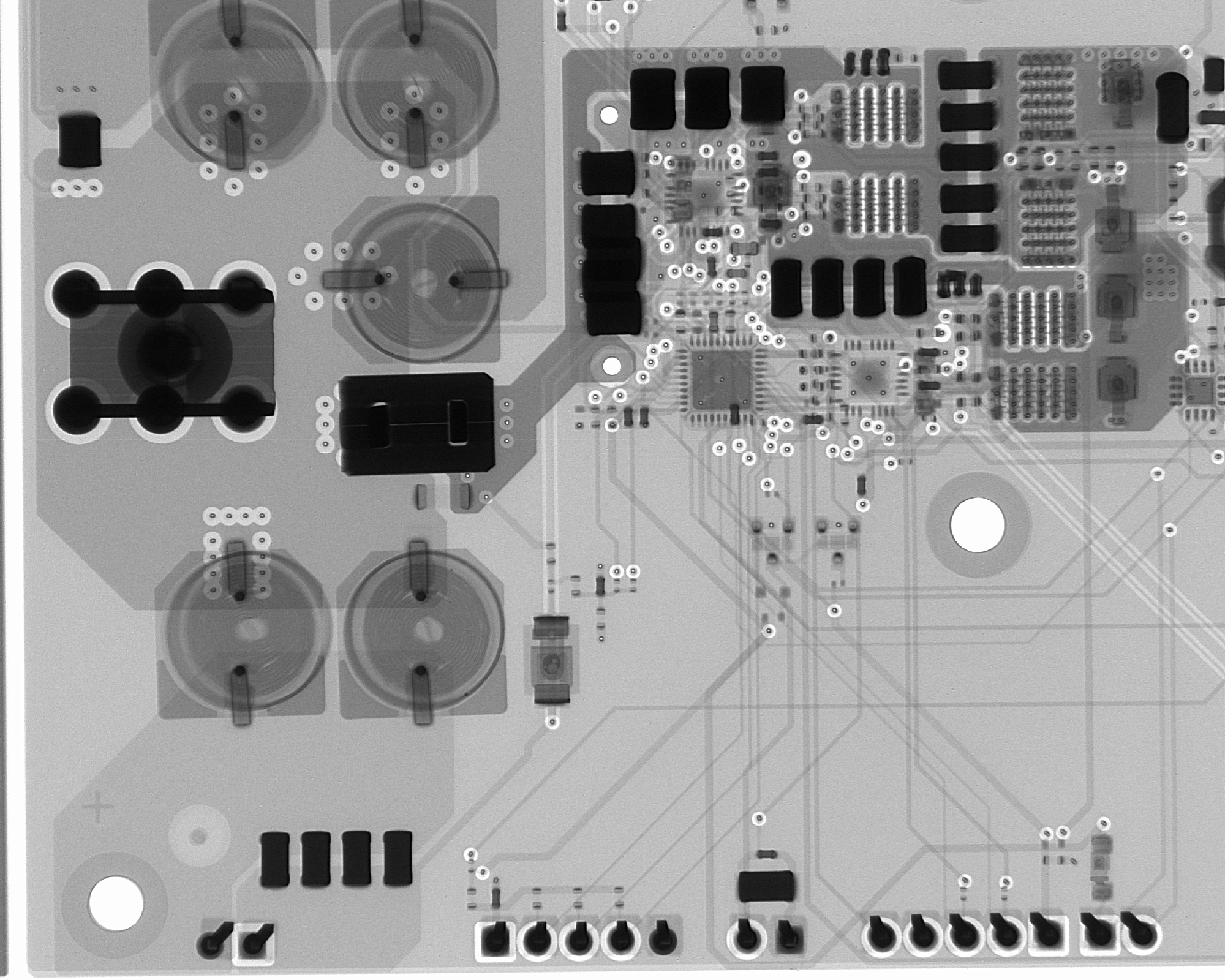

3D X-RAY ANALYSIS

NORDSON DAGE QUADRA 5

- Handling of large tables: 500 x 600 mm

- Wide field of view: 510 x 450 mm

- High power X-rays 160 kV

- Very high magnification and high definition

up to 0.35 - Inspect bare PCB, assembled boards and

any type of component - Tomographic analysis

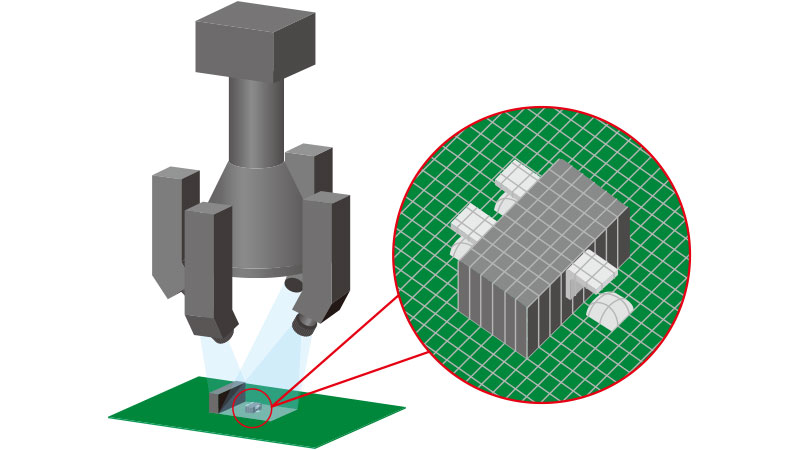

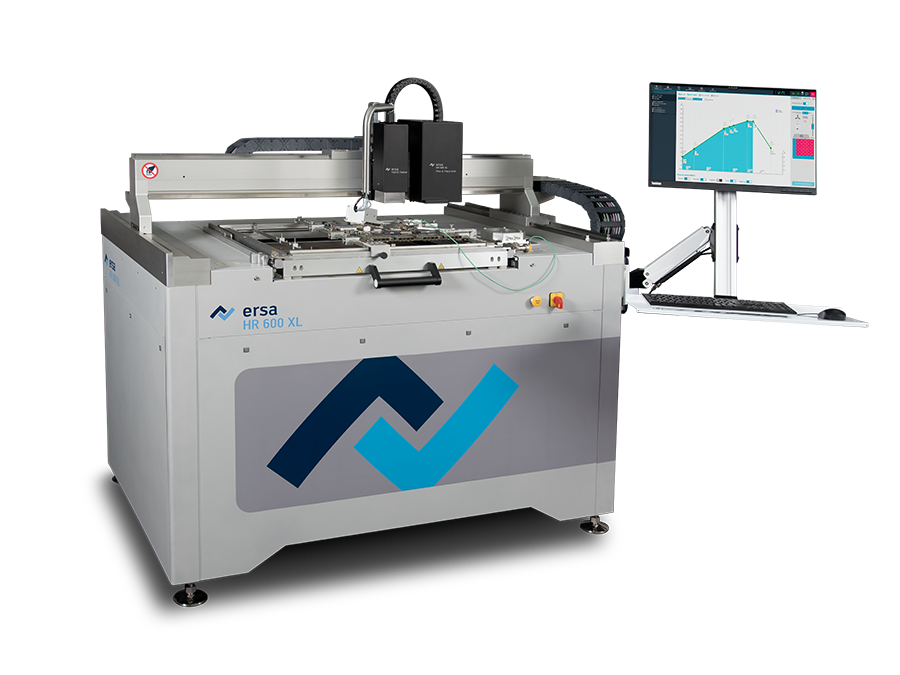

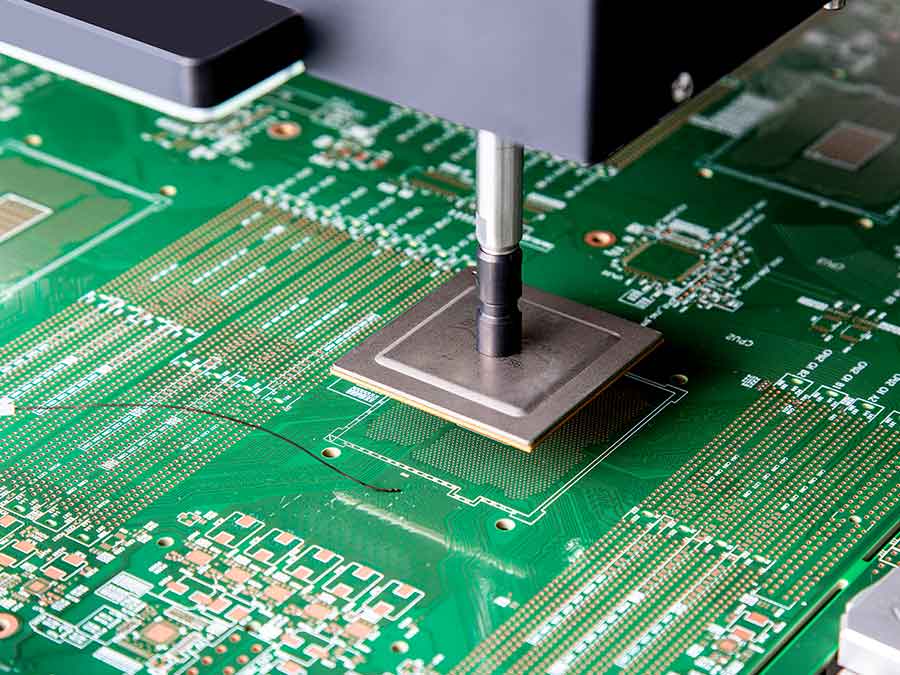

Automatic REWORK Station

ERSA HR 600 XL

- Large table dimensions: 625 x 1000 mm x 10 mm

- Minimum reworkable components: 0201

- Max. reworkable component 120×80 mm (uBGA, BGA, sockets, connectors, etc.)

- Process fully automatic for component removal, replacement and repeatability

- High precision component alignment (+/- 0.025 mm)

- Upper and lower heating by infrared, without hot air

AOI 3D OPTICAL INSPECTION

N°3 YAMAHA Ysi-V/Yri-V

- Inspection of large panels: up to 610 x 800 mm

- 3D inspection by Moiré projectors and angle inspection by 8-way projector

- High resolution camera: 20 Mpixel/5um + 4 angle cameras and high resolution 5μm/coaxial illumination

- Dedicated application for THD welding control

- New AI software with self-programming/self-learning functions